As asphalt paving cost per square foot 2025 takes center stage, this opening passage beckons readers with engaging insights into the factors, regional differences, technological innovations, and cost comparisons shaping the industry. Explore the dynamic landscape of asphalt paving costs in the upcoming year.

Delve into the key aspects influencing pricing, regional disparities, technological advancements, and comparisons with alternative materials to gain a comprehensive understanding of asphalt paving costs per square foot in 2025.

Factors Affecting Asphalt Paving Cost Per Square Foot

When considering the cost of asphalt paving per square foot in 2025, various factors come into play that can significantly influence pricing. Let’s delve into the key elements that impact asphalt paving costs in the current year.

Inflation

Inflation rates play a crucial role in determining asphalt paving costs, as they can directly affect the prices of materials, labor, and equipment. Higher inflation rates tend to drive up overall project costs, including asphalt paving.

Material Prices

The prices of raw materials such as asphalt, aggregates, and additives can fluctuate based on market demand, availability, and other economic factors. These material costs have a direct impact on the overall cost of asphalt paving projects.

Labor Costs

Labor costs for asphalt paving projects are influenced by factors such as wages, labor shortages, and project complexity. Skilled labor is essential for quality paving work, and labor costs can vary based on location and market conditions.

Technology Advancements

Technological advancements in the asphalt paving industry, such as innovative equipment and processes, can impact project costs. While advanced technologies may improve efficiency and quality, they can also come with higher upfront costs that may affect pricing.

Environmental Regulations and Sustainability Requirements

Increasing environmental regulations and sustainability requirements have become significant factors in asphalt paving costs. Compliance with environmental standards, such as recycling materials and reducing carbon footprint, can add additional costs to paving projects.

Overall, a combination of inflation, material prices, labor costs, technology advancements, and environmental regulations contributes to the variations in asphalt paving costs per square foot in 2025.

Regional Variances in Asphalt Paving Costs

When it comes to asphalt paving costs per square foot, the prices can vary significantly across different regions in the United States. These variations are influenced by a combination of local market conditions, supply chain dynamics, and weather patterns that impact the overall pricing structure.

West Coast vs. East Coast

On the West Coast, states like California and Washington tend to have higher asphalt paving costs compared to states on the East Coast like Florida and Georgia. The higher costs on the West Coast can be attributed to factors such as higher labor costs, stricter environmental regulations, and higher material costs due to transportation expenses.

Midwest vs. Northeast

In the Midwest region, states like Ohio and Illinois typically have lower asphalt paving costs per square foot compared to states in the Northeast like New York and Massachusetts. The lower costs in the Midwest can be attributed to factors such as lower labor costs, less stringent regulations, and easier access to raw materials.

Urban vs. Rural Areas

Within the same region, there can be variations in asphalt paving costs between urban and rural areas. Urban areas tend to have higher costs due to factors such as higher demand, limited access to work sites, and higher overhead expenses. In contrast, rural areas usually have lower costs as there is less competition and lower overhead expenses.

Technological Innovations Shaping Asphalt Paving Costs

Technological advancements play a crucial role in shaping the costs associated with asphalt paving projects. From the use of recycled materials to the implementation of automation and data analytics, these innovations have a significant impact on pricing trends within the industry.

Recycled Materials

Using recycled materials in asphalt paving helps reduce costs by minimizing the need for new raw materials, such as aggregates and bitumen. This sustainable practice not only lowers expenses but also contributes to environmental conservation efforts.

Autonomous Machinery and Automation

The adoption of autonomous machinery and automation in asphalt paving projects can optimize project costs by increasing efficiency and precision. These technologies streamline processes, reduce labor expenses, and minimize errors, leading to overall cost savings.

Data Analytics and IoT

Data analytics and the Internet of Things (IoT) enable contractors to make informed decisions based on real-time data, improving project planning and execution. By utilizing these technologies, paving companies can enhance efficiency, reduce downtime, and ultimately lower costs.

Sustainable Practices

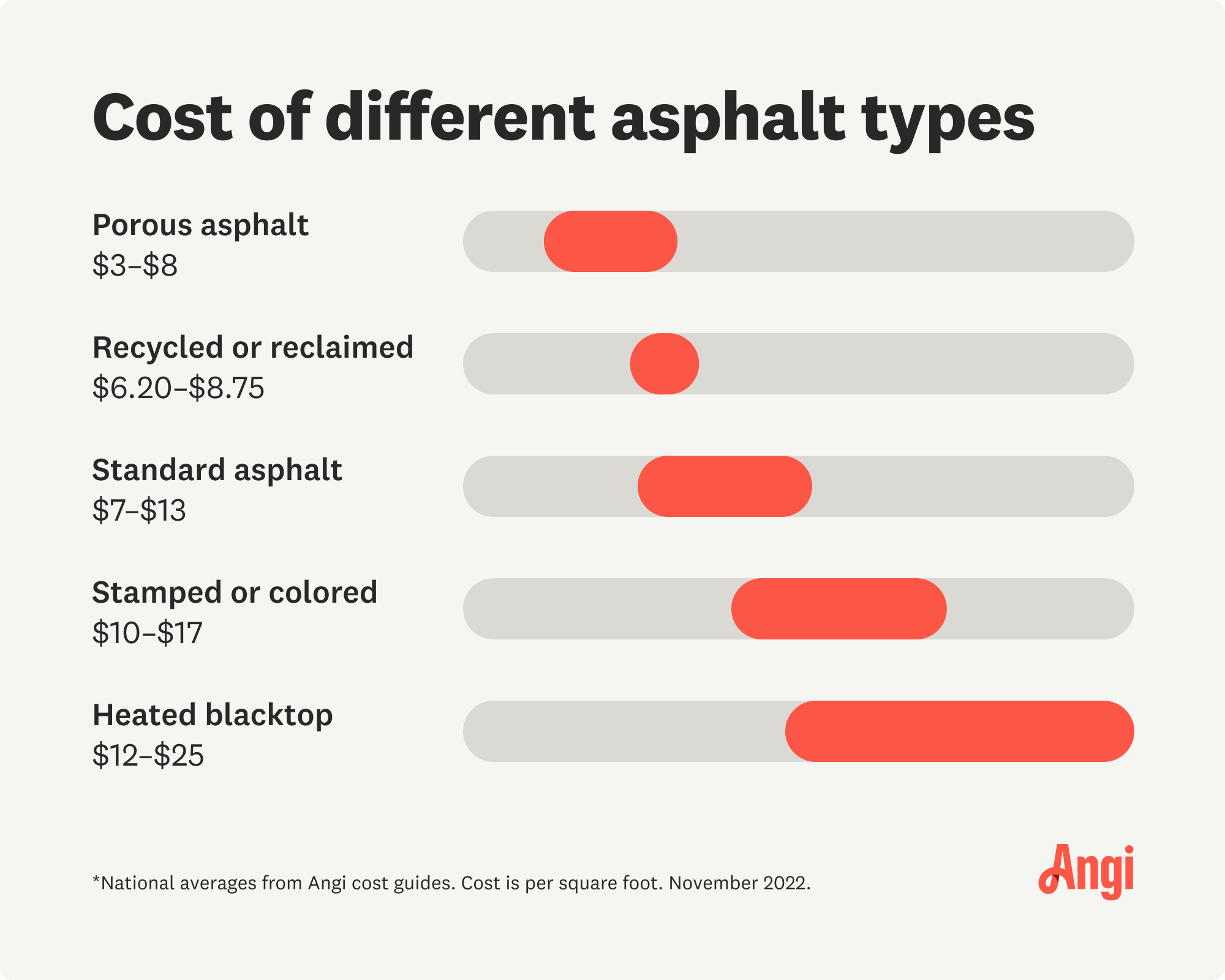

Incorporating sustainable practices like cool pavements or porous asphalt can influence pricing trends by promoting environmentally-friendly solutions. Cool pavements, for example, reflect sunlight and reduce heat absorption, lowering maintenance costs and improving durability over time. Similarly, porous asphalt allows for better water drainage, reducing the need for costly stormwater management systems.

Cost Comparison: Asphalt Paving vs. Alternative Materials

When considering paving options, it’s essential to compare the costs of asphalt paving with alternative materials like concrete, gravel, or permeable pavers. Each material comes with its own set of upfront costs, maintenance expenses, and durability factors that can impact the overall cost-effectiveness in the long run.

Asphalt Paving

Asphalt paving is known for its relatively low upfront costs compared to materials like concrete. The installation process is typically quicker and requires less labor, making it a cost-effective option initially. However, asphalt may require more frequent maintenance, such as seal coating and repairs, to maintain its durability over time.

Concrete Paving

Concrete paving, while more expensive upfront than asphalt, is known for its durability and longevity. Concrete surfaces are less prone to cracking and can withstand heavy traffic, reducing the need for frequent repairs. However, maintenance costs for concrete, such as sealing and potential replacement of damaged sections, can add up over time.

Gravel Paving

Gravel paving is often the most affordable option upfront, making it an attractive choice for budget-conscious projects. However, gravel surfaces require regular maintenance to prevent shifting and erosion, which can increase long-term costs. Additionally, gravel may not be as durable as asphalt or concrete, leading to more frequent resurfacing needs.

Permeable Pavers

Permeable pavers offer a sustainable paving solution that allows water to infiltrate the surface, reducing runoff and minimizing the risk of flooding. While permeable pavers may have higher upfront costs compared to traditional materials, they can provide long-term cost savings by reducing the need for drainage systems and stormwater management. Maintenance for permeable pavers typically involves periodic cleaning to ensure proper water infiltration.

Outcome Summary

In conclusion, the intricate web of factors impacting asphalt paving cost per square foot in 2025 unveils a nuanced picture of the industry’s future landscape. Stay informed and prepared for the evolving trends and challenges that lie ahead.